42Q Xchange

Author: Keith Fuqua | Date: January 24, 2022

Introducing 42Q Xchange. What is 42Q Xchange? 42Q Xchange is a set of APIs designed to allow connectivity between the customers’ ERP systems and 42Q, providing critical integration in their overall digital factory implementation. Traditionally, ERP integration with an MES system requires an “adapter”, a set of code which would be installed and deployed in the customer’s ERP system. An adapter provides ERP-specific code to process manufacturing-related transactions, integrates with the MES using APIs, and provides custom developed screens for monitoring, error handling and other MES-related functions. While an adapter is desirable from a connectivity standpoint, there are a substantial number of different ERP systems in use in various industries. Developing adapters for a wide variety of ERP systems is not only expensive in terms of cost, development, and overall support. It is also extremely difficult to be knowledgeable in how all ERP systems work. Additionally, some customers are understandably nervous about third party systems installing code into their ERP systems.

The approach of 42Q Xchange is to provide a standard set of secure APIs that provide all the key capabilities of an ERP adapter, without the need to develop, maintain, and deploy code into a customer’s ERP system. 42Q Xchange even allows users to create ERP style transactions, without having an ERP. This is accomplished through easy to understand templates developed in Microsoft Excel and LibreOffice Calc. A user can easily populate a template, providing all the information for a work order, BOM, and other manufacturing information, easily creating ERP work orders in a configured 42Q environment.

42Q Xchange functions in a publish/subscribe model. APIs can be called to trigger creates, updates or other transactions in a configured 42Q environment. 42Q in turn will publish common transactions that would be consumed by an ERP, such as Material Issues, Work In Progress movements, and completions. A user subscribes to the published transactions. The user can then process the published transactions in their system, thereby updating the ERP system.

One of the key advantages of 42Q Xchange is the time and effort for deployment. Because a set of code is not being installed into an ERP system, this eliminates a lot of the time, effort, security concerns, and approvals typically required to get an adapter deployed into a customer’s ERP system.

The Relevance of

OEE and TEEP For

Manufacturers Today

Author: Bobby Hanna | Date: November 24, 2021

Overall Equipment Effectiveness (OEE) is a measure of performance in the domain of manufacturing. It encompasses the maturity level of the shop floor from a standpoint of productivity, quality and availability of the assets to ensure operational efficiency and in turn address business results. OEE is measured as the product of productivity, quality and availability and is expressed as a percentage.

This measure truly indicates the KPI of a manufacturing process. OEE gives a true reflection of how a manufacturing line is performing and hence this metric becomes a primary source of data to drive manufacturing excellence.

Another measure of performance is Total Effective Equipment Performance (TEEP), which in addition to the parameters of OEE, takes into account the utilisation aspect of the manufacturing line. TEEP is measured as the product of productivity x quality x availability x utility expressed as a percentage.

A real-time data acquisition of these parameters will help the operational teams to gain an insight into how their lines are performing. Since manufacturing lines are performing tasks which are time deterministic, data acquisition at source becomes a primary challenge. Real-time data visibility will enable operations team to take data based decisions within the stipulated takt time to ensure seamless flow of downstream processes

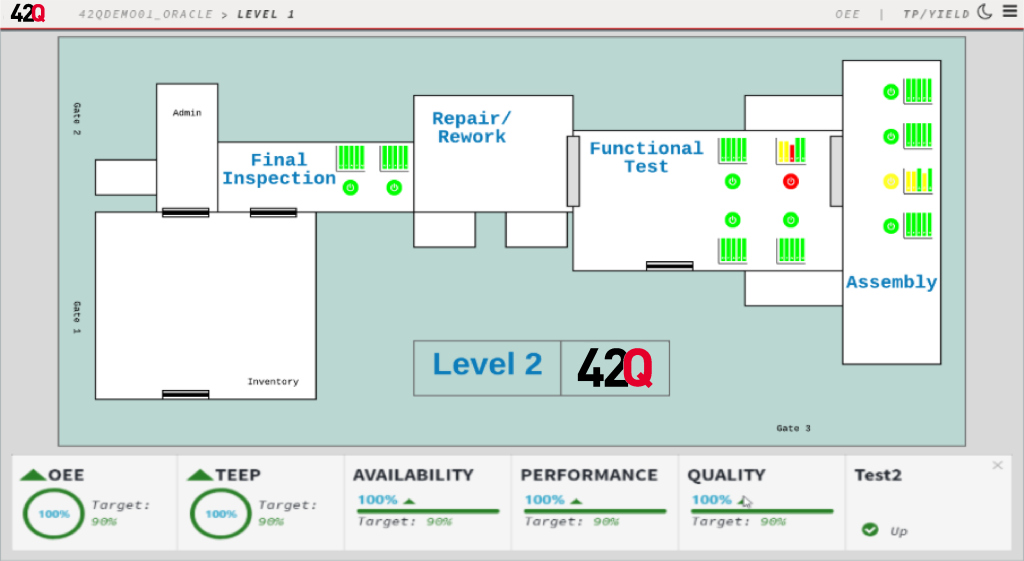

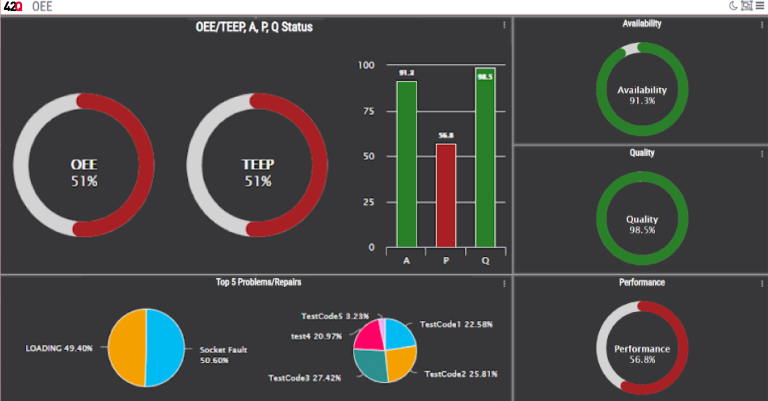

42Q functionalities encompasses these aspects and gives a holistic view of how each parameter is behaving and gives an insight through descriptive analytics. 42Q gives you a single location for gathering all the necessary information for OEE & TEEP calculations. Information such as Throughput, Yield, Cycle Time, Machine Up/Down Time, Downtime Root Cause, etc. can then be broken down to the work shift and operator level as shown below.

The default reports include the following:

- OEE & TEEP Dashboard

- Downtime Root Cause Analysis

- Downtime Trend Analysis

- OEE Trend Analysis

We have the capability to acquire these data sets and portray them in a way which truly reflects time based behavior of the manufacturing line. In 42Q, one has access to reports and dashboards on the real-time OEE & TEEP statistics. This fully customizable panel gives you the ability to monitor the current manufacturing line readings as compared to expected target results. As a result, 42Q allows plant managers to quickly troubleshoot critical problems in real-time.

Furthermore, 42Q Live enables you to see the real-time status of critical stations on your manufacturing floor. This allows you to send Alerts and Notifications based on threshold settings.